SRP Sand Katcher

Simple, effective solids fallback protection for artificial lift

FALLBACK designs, manufactures, and sells specialized artificial lift equipment that can enhance the performance of any manufacturer’s sucker rod pumps.

THE SOLIDS FALLBACK CHALLENGE

Erosive wear

Abrasive wear

Stuck pump

Parted rod

Solids-laden fluid columns in production tubing cause sucker rod well interventions and nuisance shutdowns.

A pump installed at a depth of 10,000 ft with 0.1% solids in the production fluid can result in 10 ft of solids accumulation on top of the pump or traveling valve.

INTRODUCING THE

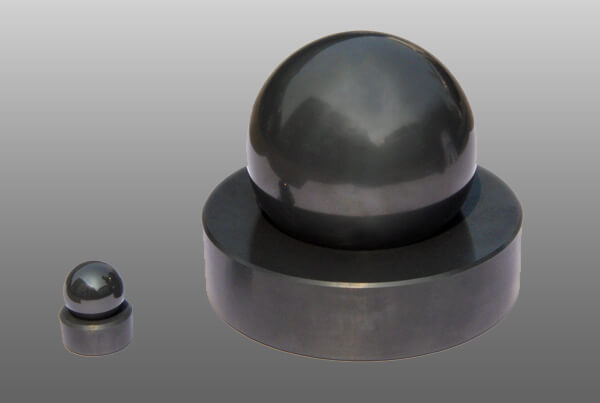

SRP SAND KATCHER

YOU PUMP IT. WE KATCH IT.

VALVE

PROTECTION

The SRP Sand Katcher™ avoids interventions and shutdowns caused by suspended solids settling on standing and traveling valves during a shutdown.

INTEGRAL ATTACHMENT

The SRP Sand Katcher™ seamlessly integrates within the tubing to securely fasten to the rod string, guaranteeing a straightforward, sturdy installation.

SOLIDS

MANAGEMENT

The SRP Sand Katcher™ catches falling solids during stoppages, contains these solids during downtime, and cleans the solids from the device upon restart.

KEY FUNCTIONS

Solids capture: Installed above the sucker rod pump, the SRP Sand Katcher™ efficiently traps fallback solids to minimize operational disruptions.

Containment: Multiple chambers securely contain solids, preventing settling on the sucker rod pump.

Streamlined restart: Upon starting up, the SRP Sand Katcher™ ensures the transport of stored solids to the surface.

AVOID INTERVENTIONS AND NUISANCE SHUTDOWNS

Catch solids, Contain solids, Clean out solids.

The system contains solids storage chambers with no moving parts or physical barriers to the SRP, ensuring seamless operation. It features self-cleaning capabilities for collected solids and utilizes common API pin ends.

With straightforward installation, the design safeguards the SRP to ensure top-notch reliability, facilitate chemical treatment, ensure production, and prepare for subsequent shutdowns.